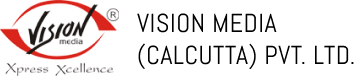

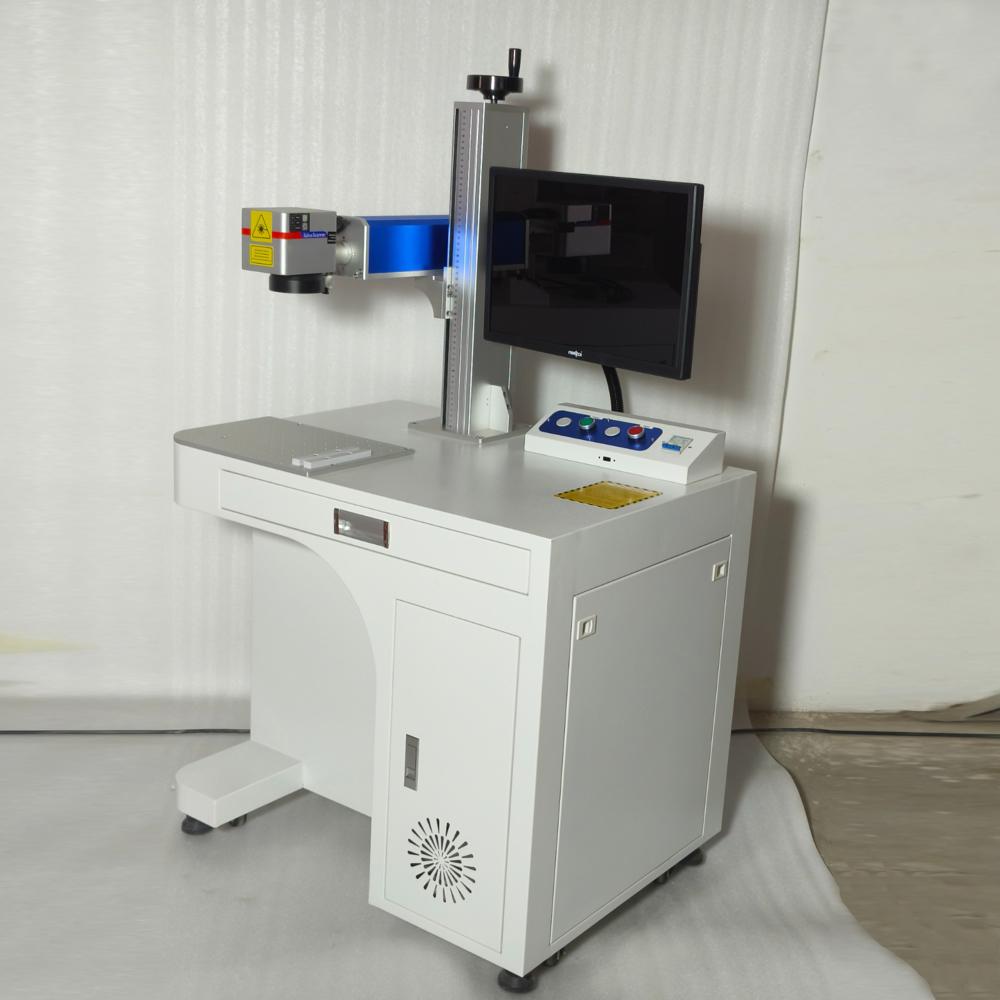

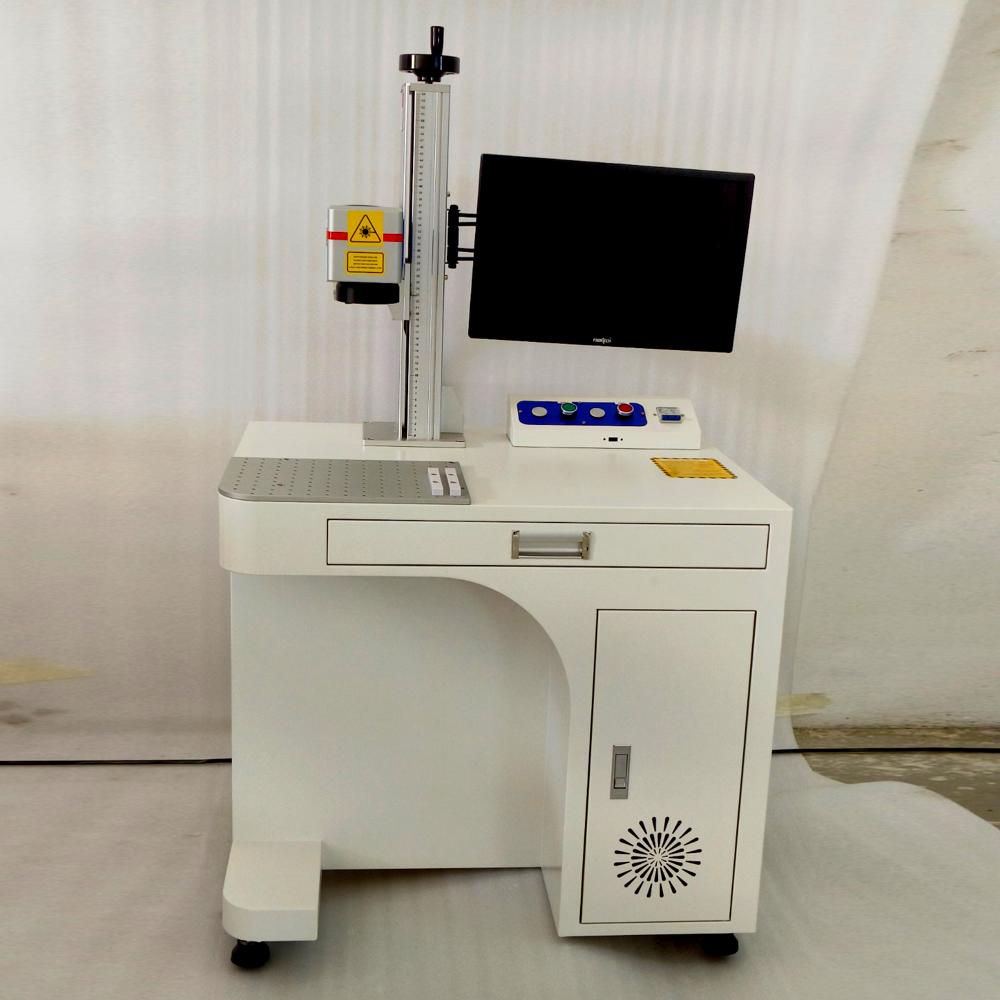

VM-FL-W30-PC Vision Media Fiber Laser Marking Machine

185000.0 INR/Unit

Product Details:

- Phase Single

- Technology Laser

- Power 220 Volt (v)

- Product Type Fiber Marking Machine

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness .5 Millimeter (mm)

- Click to View more

X

VM-FL-W30-PC Vision Media Fiber Laser Marking Machine Price And Quantity

- 1 Unit

- 185000.0 INR/Unit

VM-FL-W30-PC Vision Media Fiber Laser Marking Machine Product Specifications

- 85 Kilograms (kg)

- 10000 mm/s

- PLC Control

- 1000 Volt (v)

- DXF

- Single

- .5 Millimeter (mm)

- Automatic

- 750x600x1270 Millimeter (mm)

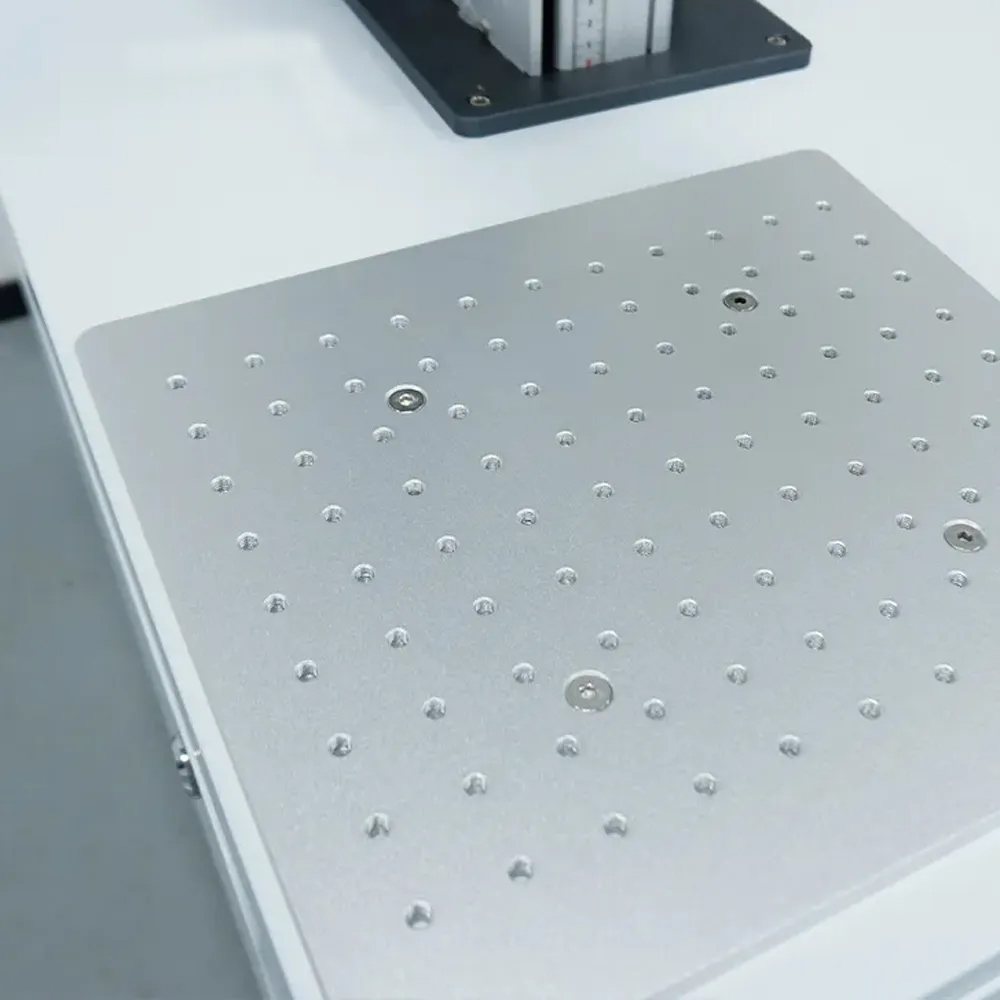

- 100 Square Millimeter (mm2)

- Fiber Laser

- Yes

- Fiber Marking Machine

- 220 Volt (v)

- Laser

- Simple Control, High Performance, Lower Energy Consumption, High Efficiency, Low Noise

- Normal

- Metal

- EZ-Cad2

- Air Cooling

VM-FL-W30-PC Vision Media Fiber Laser Marking Machine Trade Information

- Ex-Kolkata

- Cash in Advance (CID)

- 5 Unit Per Week

- 5 Days

- No

- Contact us for information regarding our sample policy

- Machine packed in a Wooden Carton with proper Foam cushioning to avoid transportation damage

- Asia

- All India

- CE Certified

Product Description

Features -

- High Quality Laser Beam for fine marking high precision.The minimum line width of laser can reach to 0.02 mm

- Low consumption, energy saving 0.5 KW for whole machine

- Free maintenance & long service life

- Fibre Laser system dont require any maintenance & their diode life is higher than 100 thousand hours

- Enhances the aesthetical & monetary value of products, product tracking

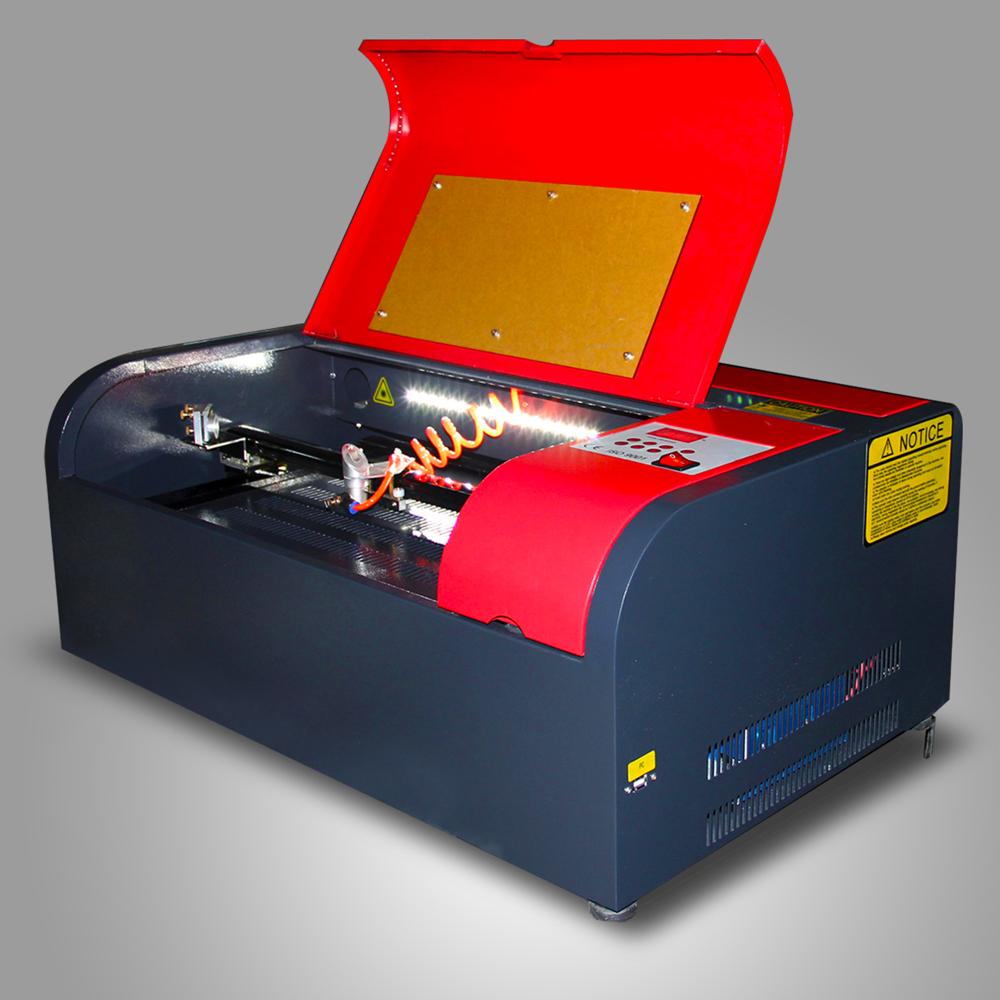

Application:

- Marking on electronic components

- Button

- Cover

- Jewelleries

- Molds, etc

Powerful Precision with Automated Control

Equipped with a fiber laser and PLC control, the VM-FL-W30-PC guarantees consistently accurate marking on a variety of metals. Its integrated EZ-Cad2 software simplifies operation, while automated functions minimize manual intervention, leading to higher throughput and minimal operator error in demanding industrial or commercial environments.

Energy-Efficient and Quiet Operation

This fiber laser machine stands out for its high efficiency and low energy consumption, thanks to advanced technology and air cooling. Its low noise output makes it suitable for workplaces that prioritize a comfortable, distraction-free environment, even with continuous use over long shifts.

Versatile Application and Simple Integration

Supporting DXF file formats and featuring a compact design, the VM-FL-W30-PC adapts seamlessly to various marking needs in metalworking, manufacturing, and labeling industries. Its straightforward software interface and robust hardware allow for hassle-free installation and rapid deployment on your production floor.

FAQs of VM-FL-W30-PC Vision Media Fiber Laser Marking Machine:

Q: How does the VM-FL-W30-PC Fiber Laser Marking Machine operate and what technology does it use?

A: The machine utilizes advanced fiber laser technology to mark metals with high precision. It operates through an automated PLC control system and user-friendly EZ-Cad2 software, ensuring efficient performance with consistent results.Q: What materials can be processed with this machine and what is the maximum cutting thickness?

A: This laser marking machine is specifically designed for metal materials. It can cut and mark metals with a maximum thickness of 0.5 millimeters, making it ideal for a range of industrial applications.Q: When is it recommended to use air cooling instead of water cooling for laser machines?

A: Air cooling, as featured in the VM-FL-W30-PC, is suitable when energy efficiency, low maintenance, and quiet operation are prioritized. Its effective here due to the machines high performance yet relatively low heat generation.Q: Where can this machine be purchased and who are the main customers in India?

A: This model is available through authorized distributors, importers, and wholesalers across India. Its ideal for businesses in the metal processing, manufacturing, marking, and labeling sectors.Q: What is the recommended process for setting up and starting the machine?

A: Installation involves placing the unit in a stable work area, connecting it to a 220V single-phase power supply, and setting up the EZ-Cad2 control software. Once the initial parameters and DXF graphics are loaded, marking can begin automatically via the PLC system.Q: How does users benefit from the combination of high cutting speed and computerized control?

A: With a cutting speed of up to 10,000 mm/s and full computerization, users achieve faster processing times, reduced labor, and increased accuracy. The automated system minimizes errors and enhances overall productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free