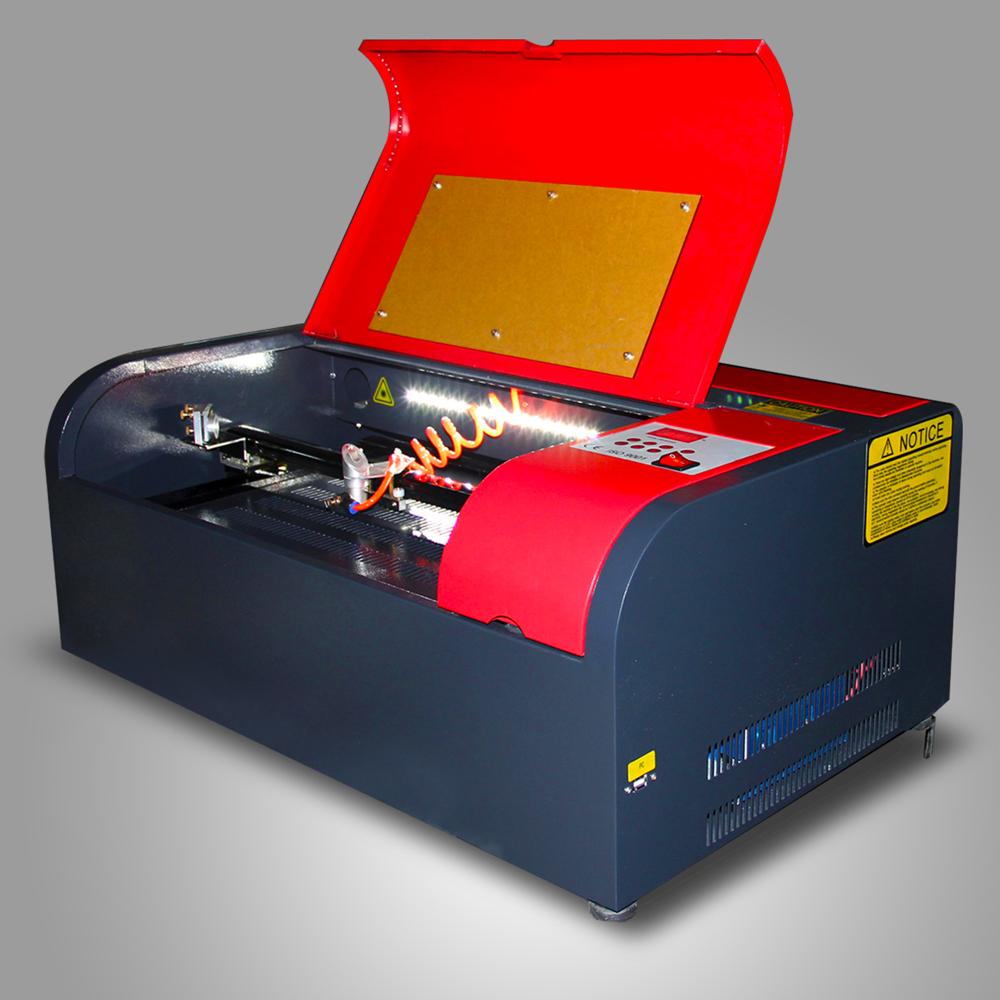

Laser Engraving Cutting Machine (80W)

325000.0 INR/Piece

Product Details:

- Phase Single

- Power 80 Watt (w)

- Usage & Applications Laser Cutting & Engraving

- Technology Laser

- Working Area 864 Square Inch (in2)

- Product Type Engraving Cutting Machine

- Laser Type CO2

- Click to View more

X

Laser Engraving Cutting Machine (80W) Price And Quantity

- 325000.0 INR/Piece

- 1 Piece

Laser Engraving Cutting Machine (80W) Product Specifications

- Laser Cutting & Engraving

- 80 Watt (w)

- 5 Millimeter (mm)

- 600 mm/s

- Automatic

- 340 Kilograms (kg)

- Low Noise, Simple Control, High Performance, ECO Friendly, Lower Energy Consumption, High Efficiency

- Other

- Human Machine Interface

- 220 Volt (v)

- RD Works

- Single

- Acrylic, Crystal, Leather, Glass, Paper, Plastic, Stone, Wood, Plywood, Rubber

- CO2

- Normal

- 145 X 101 X 111 Centimeter (cm)

- PLT

- Yes

- 864 Square Inch (in2)

- Laser

- Engraving Cutting Machine

- 864 Square Inch (in2)

- Water Cooling

- 10 Pcs/hr

- 1 year

Laser Engraving Cutting Machine (80W) Trade Information

- Kolkata,West Bengal,India

- Cash Advance (CA)

- 1 Piece Per Day

- 1 Days

- No

- Within a certain price range free samples are available

- Our product are extensively exported to Asia and thus we make sure our range is suitably packed to avert any kind of damage during transportation. Following are the list of the packaging material used by us Corrugated boxes, Cartons and other material

- Asia

- All India

- Certified

Product Description

Laser Engraving Cutting Machine 80 W is a high performance industrial unit that makes it very easier to cut or engrave designs over the metallic nonmetallic and alloyed materials It is equipped with a high intensity laser which is fixed with top quality electrical drives to easily control the cutting and engraving directions The marking area of the offered Laser Engraving Cutting Machine 80 W is 600 X 900 with dimensions in millimeters

Features of Laser Engraving Cutting Machine:

- High stability control card driver DSP control and 2h stepper motor for high engraving speed while ensuring quality Supports all major file formats

- Good quality Co2 laser tube equipped with water cooling system

- Powerful exhaust fan sucks out smoke dust from the machine and keep the machine clean

- Matching air pump to supply air to the laser head prevents burn marks and keeps lens clear

- Red dot pointer used for previewing helps in accurate engravingcutting

- Imported highly stable guide rail improves precision

- Imported long lasting lens and mirrors

- Powerful water chiller to manage temperature increases longevity of laser tube

Product Details of Laser Engraving Cutting Machine :-

- Lenses - Imported long lasting lens

- Laser power W - 80

- Engraving speed mmmin - 1000 mms

- Laser Type - CO2

- Dimension LWH - 145 X 101 X 111 cm

- Compatible Software - Corel draw Auto CAD

- Cooling Mode - Water Cooling

- Model - VL 6090

- Cutting Speed mm per min - 600 mms

- Working Area mm - 600mm 900mm

- Weight kg - 340 kg

- Warranty - 1 Year

- Interface Type - LED Screen USB Interface

- Size - 36 inch 24 inch

- Material - Stone Glass Acrylic Rubber Leather Wood Paper Board Metal Plastic Fabric MDF

High-Precision, Large Working Area

With a 600x900mm work and engraving area and precision tolerance of 0.01mm, this machine is ideal for detailed projects. Its stable control card and automatic drive ensure consistent results for both intricate engraving and rapid cutting, suitable for a range of professional applications.

Versatile Material Capability

Engineered to handle an array of non-metal materials such as acrylic, wood, plastic, leather, MDF, stone, paper, and crystal, this laser cutter is designed for businesses seeking flexibility. Its 80W CO2 laser can cut up to 10mm thick acrylic and handle coated metals with ease.

Advanced Cooling and Efficient Design

The integrated water cooling system maintains optimal temperature, supporting uninterrupted operation in environments between 545C. This energy-efficient, low-noise machine is tailored for productivity and longevity, making it an eco-friendly investment for modern workshops.

FAQs of 80 W Laser Engraving Cutting Machine:

Q: How does the 80 W Laser Engraving Cutting Machine ensure accuracy during operation?

A: This machine utilizes a high-stability control card, stepper motor system, and automatic drive to achieve a precision of 0.01mm, ensuring exceptionally accurate cutting and engraving results across a variety of materials.Q: What types of materials can be processed with this laser cutting machine?

A: The machine is capable of handling a variety of non-metal materials, including glass, acrylic, stone, wood, crystal, leather, paper, rubber, plastic, plywood, MDF, coated metals, fabric, and organic glass, making it highly versatile for different production needs.Q: When is the best time to perform maintenance on the laser engraver?

A: Routine maintenance should be performed after every extensive work session or in accordance with the manufacturers guidelines to ensure optimal performance. Regularly check the laser tube, water cooling system, and optics for cleanliness and function.Q: Where should the 80 W laser engraving machine be installed for optimal operation?

A: It is best to operate the laser cutting machine in a clean, dust-free workspace with adequate ventilation. Ensure the ambient temperature remains within the 545C range for effective water cooling and optimal machine performance.Q: What is the process for using the laser cutter on different materials?

A: Select the appropriate power and speed settings depending on the materialacrylic, wood, fabric, or coated metalsusing the included RD Works software. The machines interface allows users to upload and manage designs, ensuring smooth engraving or cutting cycles.Q: How does the water cooling system benefit the machines performance?

A: The water cooling system helps maintain safe and efficient operating temperatures, preventing the laser tube from overheating and extending the lifespan of the equipment, especially during continuous or high-speed operations.Q: What are the key benefits of using this 80 W laser engraving machine in a workshop or production environment?

A: Key benefits include high cutting and engraving speeds, wide material compatibility, energy efficiency, low noise levels, and simple control systems. Its robust build and one-year warranty provide reliability for business growth and productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free