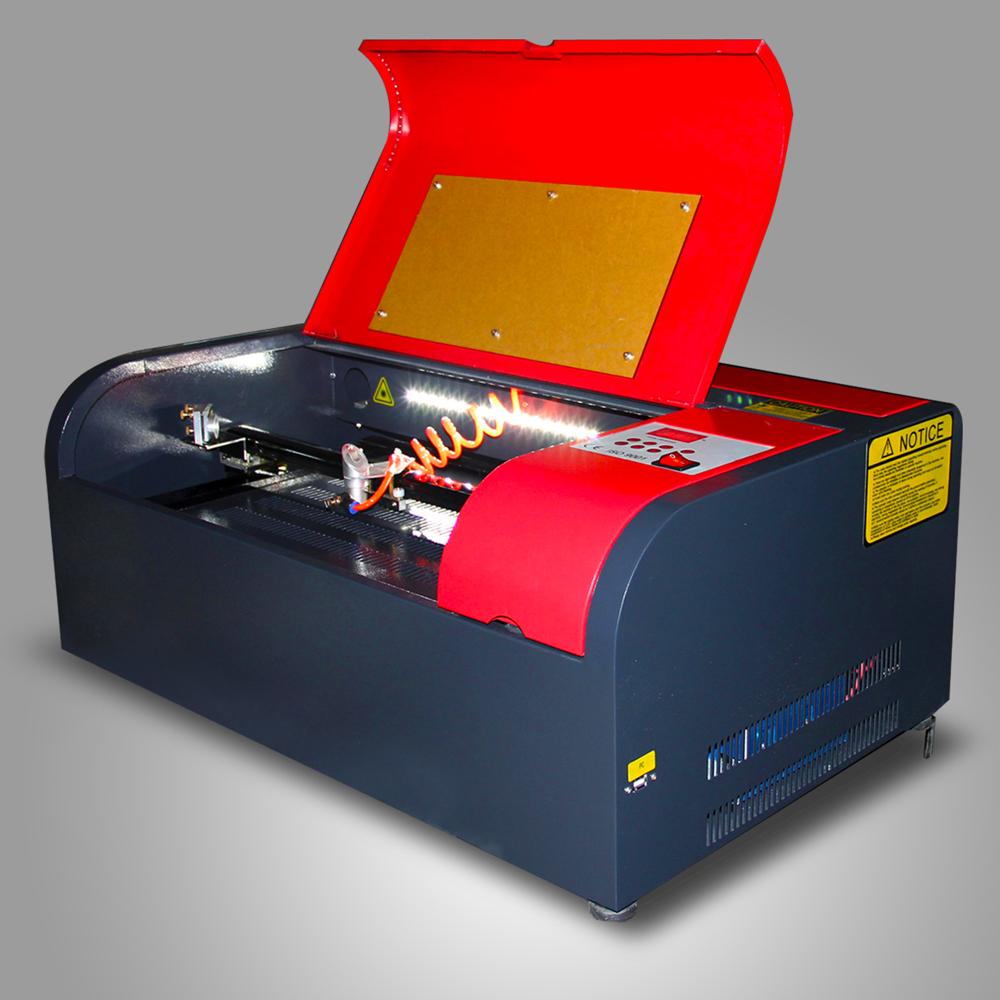

100 W Laser Engraving Cutting Machine

375000.00 INR/Piece

Product Details:

- Product Type Laser Engraving Cutting Machine

- Computerized No

- Automatic Grade Semi Automatic

- Voltage 220-240 Volt (v)

- Feature Simple Control

- Warranty 1 Year

- Click to View more

X

100 W Laser Engraving Cutting Machine Price And Quantity

- 1 Piece

- 375000.00 INR/Piece

100 W Laser Engraving Cutting Machine Product Specifications

- Laser Engraving Cutting Machine

- 1 Year

- Simple Control

- Semi Automatic

- No

- 220-240 Volt (v)

100 W Laser Engraving Cutting Machine Trade Information

- Kolkata,West Bengal,India

- 5 Piece Per Day

- 1 Week

- Contact us for information regarding our sample policy

- Our product are extensively exported to Asia and thus we make sure our range is suitably packed to avert any kind of damage during transportation. Following are the list of the packaging material used by us : Corrugated boxes, Cartons and other material

- All India

Product Description

Laser Engraving Cutting Machine (100 W)

- Size :- 3 feet x 4 feet

- Working Area :- 1300 mm x 900 mm

- Applicable Material :- Acrylic, Stone, Glass, Rubber, Leather, Wood, Paper Board, Metal, Plastic, Fabric, MDF

Features

- High stability control card / driver, DSP control and 2h stepper motor for high engraving speed while ensuring quality. Supports all major file formats.

- Good quality Co2 laser tube equipped with water cooling system

- Powerful exhaust fan sucks out smoke & dust from the machine and keep the machine clean

- Matching air pump to supply air to the laser head, prevents burn marks and keeps lens clear

- Red dot pointer used for previewing, helps in accurate engraving/cutting

- Imported highly stable guide rail improves precision

- Imported long lasting lens and mirrors

- Powerful water chiller to manage temperature increases longevity of laser tube

Product details

| Lenses | Imported long lasting lens |

| Laser power | 100 |

| Engraving speed | 1000 mm/s |

| Laser Type | CO2 |

| Dimension | 183 X 132 111 cm |

| Compatible Software | Corel draw, Auto CAD |

| Cooling Mode | Water Cooling |

| Model | VL - 1390 |

| Cutting Speed | 600 mm/s |

| Working Area | 1300mm * 900mm |

| Weight | 400 kg |

| Warranty | 1 Year |

| Interface Type | LED Screen & USB Interface |

| Size | 3 ft x 4 |

| Material | Acrylic, Stone, Glass, Rubber, Leather, Wood, Paper Board, Metal, Plastic, Fabric, MDF |

Durable and Efficient Metal Construction

This laser machine features a sturdy metal body, providing exceptional durability and stability during operation. Its design not only extends the lifespan of the equipment but also supports consistent and accurate performance even with intensive use. The reliable build is well-suited for industrial environments where longevity and strength are essential.

Generous Working Area for Large Projects

With a spacious working area of 1300 x 900 mm, this laser engraving and cutting machine is ideal for handling large-scale projects. The ample space allows for greater flexibility in material size and application, increasing productivity while maintaining precision on every cut or engraving.

Simple Control and Easy Operation

Designed for straightforward use, the machine offers simple control and semi-automatic functioning. This ensures that users, whether beginners or seasoned operators, can manage the system efficiently, minimizing the learning curve and reducing operator fatigue. Its streamlined controls make it a practical choice for busy workshops.

FAQs of 100 W Laser Engraving Cutting Machine:

Q: How do I operate the 100 W Laser Engraving Cutting Machine?

A: The machine features simple controls and a semi-automatic interface, allowing easy operation. Users can set up and adjust parameters manually without advanced programming skills. For safety and best results, always refer to the instruction manual provided with the machine.Q: What types of projects is this laser machine suitable for?

A: Thanks to its versatile 1300 x 900 mm working area and 100 W power, this laser machine can handle a diverse range of engraving and cutting tasks on metal surfaces, making it suitable for sign making, industrial parts, artwork, and customized fabrication tasks.Q: When is maintenance required for this laser machine?

A: Regular maintenance, such as cleaning the lens and checking alignment, is recommended after significant use or at least once a month. Inspecting mechanical parts and replacing worn-out components as needed ensures optimal and safe operation throughout its service life.Q: Where can I install and use this machine effectively?

A: This machine is designed for industrial or workshop use. Ensure installation in a well-ventilated area with a stable, level surface. The sturdy metal construction and 400 kg weight require proper handling and sufficient floor space to accommodate its dimensions (183 x 132 x 111 cm).Q: What is the process for engraving or cutting materials?

A: To engrave or cut, users manually adjust settings and position the workpiece inside the working area. The semi-automatic operation guides the laser to precisely cut or mark the material according to the set parameters, delivering reliable, high-quality results.Q: What are the key benefits of using this semi-automatic laser machine?

A: Users benefit from high-speed and precise cuts, durability, user-friendliness, and versatility. Its design maximizes efficiency and reliability for various metal processing needs, while the 1-year warranty offers added assurance for long-term use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS