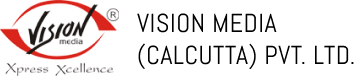

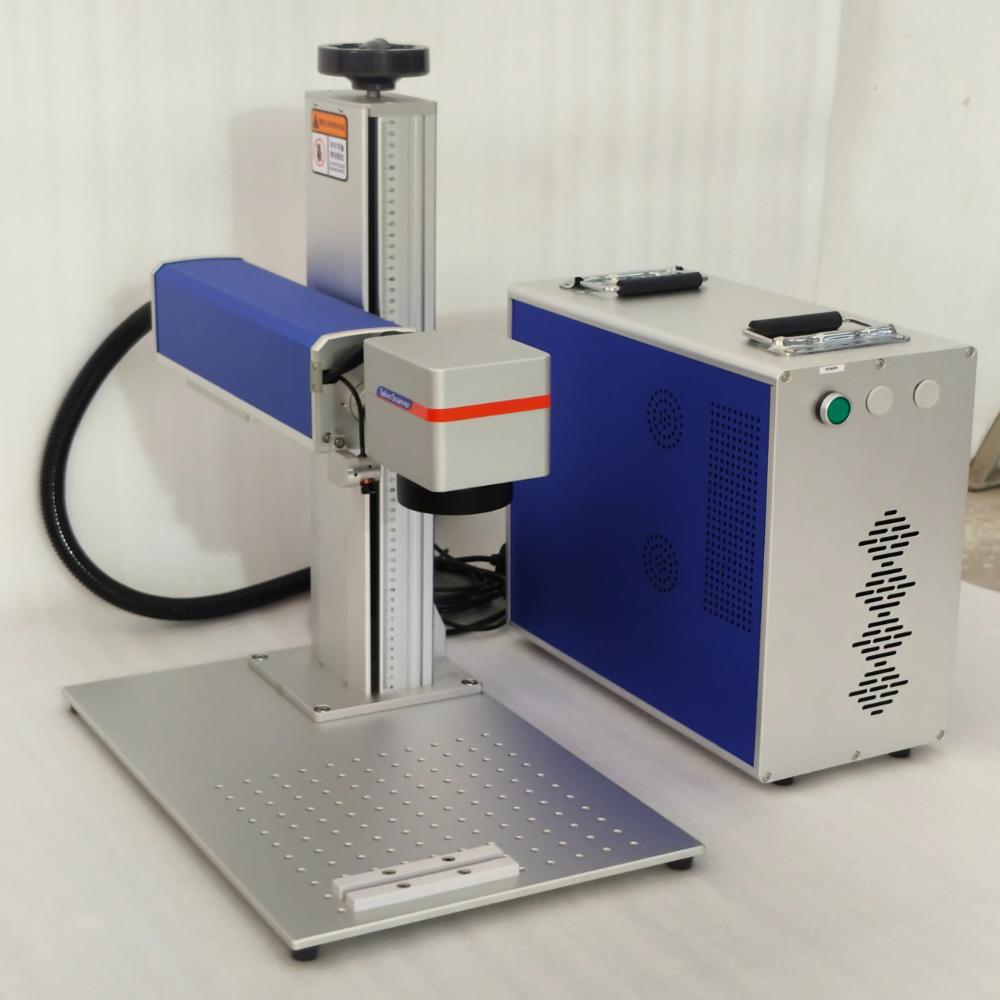

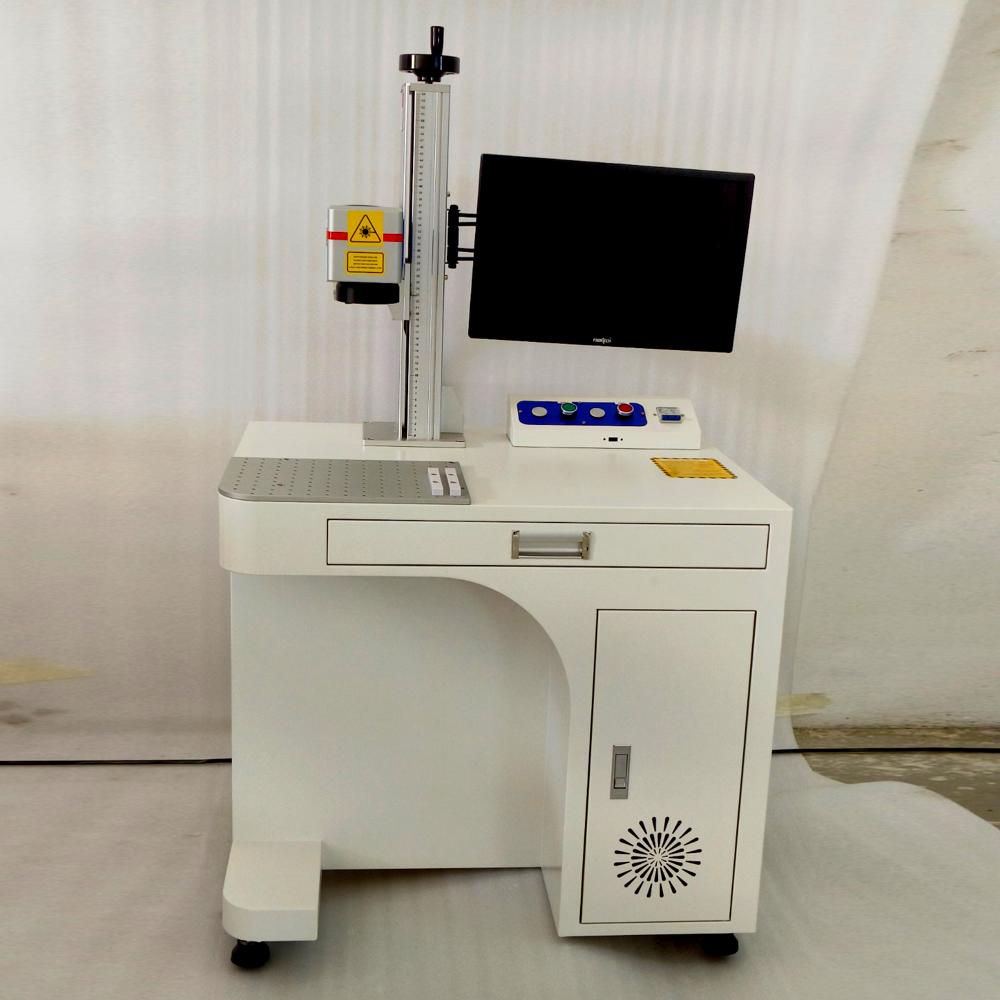

Laser Engraving Cutting Machine (40 W)

95000.0 INR/Unit

Product Details:

- Technology Laser

- Working Area 800 Square Centimeter (cm2)

- Power 40 Watt (w)

- Usage & Applications Laser Engraving & Cutting

- Phase Single

- Product Type Laser Machine

- Laser Type CO2

- Click to View more

X

Laser Engraving Cutting Machine (40 W) Price And Quantity

- 95000.0 INR/Unit

- 1 Unit

- 95000.00 - 115000.00 INR/Unit

Laser Engraving Cutting Machine (40 W) Product Specifications

- Automatic

- Laser

- Yes

- Acrylic, Leather, Paper, Plastic, Plywood, Rubber, Wood

- 1000 mm/s

- 800 Square Centimeter (cm2)

- 40 Kilograms (kg)

- Simple Control

- 80*50*31 Centimeter (cm)

- CorelDraw with Plugin

- 40 Kg

- 2 Millimeter (mm)

- Normal

- 1 year on Electronic part

- 800 Square Centimeter (cm2)

- Water Cooling

- Human Machine Interface

- 220 Volt (v)

- Laser Machine

- PLT

- CO2

- Single

- Other

- 40 Watt (w)

- Laser Engraving & Cutting

Laser Engraving Cutting Machine (40 W) Trade Information

- Kolkata,West Bengal,India

- 1-10 Unit Per Day

- 1 Days

- Contact us for information regarding our sample policy

- Our product are extensively exported to Asia and thus we make sure our range is suitably packed to avert any kind of damage during transportation. Following are the list of the packaging material used by us : Corrugated boxes, Cartons and other material

- Africa, Asia, Middle East

- All India

Product Description

Laser Engraving Cutting Machine (40 W)

- Size :- 8 inch x 16 inch

- Working Area :- 200 mm x 400 mm

- Applicable Material :-Acrylic, Stone, Glass, Rubber, Leather, Wood, Paper Board, Metal, Plastic, Fabric, MDF

Features

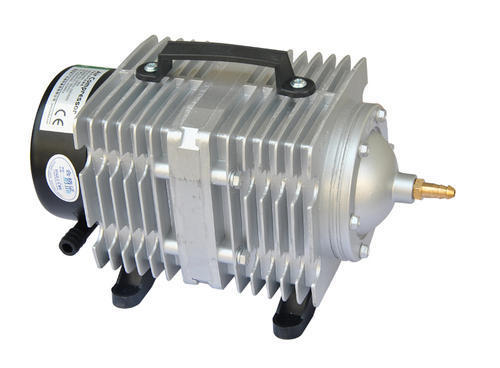

- High stability control card / driver, DSP control and 2h stepper motor for high engraving speed while ensuring quality. Supports all major file formats.

- Good quality Co2 laser tube equipped with water cooling system

- Powerful exhaust fan sucks out smoke & dust from the machine and keep the machine clean

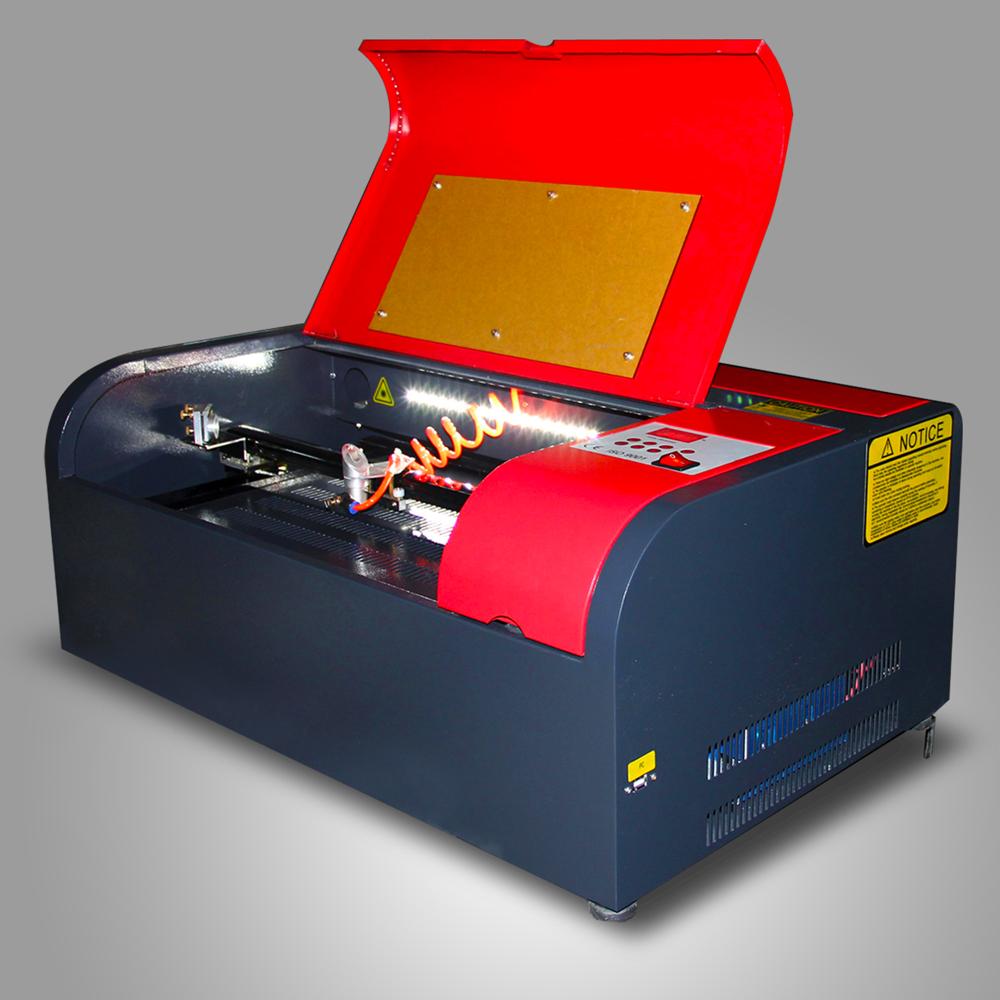

- Matching air pump to supply air to the laser head, prevents burn marks and keeps lens clear

- Red dot pointer used for previewing, helps in accurate engraving/cutting

- Imported highly stable guide rail improves precision

- Imported long lasting lens and mirrors

- Powerful water chiller to manage temperature increases longevity of laser tube

Product Details

|

Lenses |

Imported long lasting lens |

|

Laser power |

40 W |

|

Engraving speed |

400 mm/s |

|

Automatic Grade |

Automatic |

|

Laser Type |

CO2 |

|

Dimension |

80 X 50 X 31 cm |

|

Compatible Software |

Corel draw, Auto CAD |

|

Cooling Mode |

Water Cooling |

|

Model |

VL - 2040 |

|

Cutting Speed |

200 mm/s |

|

Working Area |

200mm * 400mm |

|

Weight |

38 kg |

|

Warranty |

1 Year |

|

Interface Type |

LED Screen & USB Interface |

|

Brand |

Vision Media |

|

Size |

8 inch x 16 inch |

|

Material |

Stone , Glass , Acrylic , Rubber ,Leather , Wood , Paper Board , Metal , Plastic , Fabric , MDF |

Versatile Laser Precision

Engineered for versatility, this 40W laser engraving and cutting machine offers exceptional accuracy of 0.01mm, making it suitable for detailed work across an array of non-metal materials such as wood, acrylic, fabric, MDF, stone, and more. Its 200mm x 400mm working area enables both compact and moderately large projects, ideal for professional or creative tasks.

User-Friendly Operation

Equipped with a high-stability control card and a stepper motor, this machine ensures smooth and repeatable motion. The intuitive control system supports easy operation and precise customization, while water cooling maintains optimal temperatures for continuous use. With dual voltage options, it fits well in diverse industrial settings.

Reliable and Durable Design

Built to last with a lifespan of 3000 laser hours and a robust construction, this machine performs reliably for demanding workloads. Weighing 38kg, it maintains stability during operation, while accommodating operating temperatures from 5C to 45C and humidity levels between 5% and 95%. Its efficient energy use makes it a practical addition to any workspace.

FAQs of Laser Engraving Cutting Machine (40 W):

Q: How does the Laser Engraving Cutting Machine (40W) operate and what materials can it process?

A: This machine utilizes a 40W CO2 laser to engrave and cut materials by focusing a high-intensity laser beam onto the target. It is capable of processing non-metallic materials like acrylic, wood, leather, rubber, fabric, plastic, MDF, stone, organic glass, and coated metals.Q: What are the main advantages of using this laser engraver in a professional or industrial setup?

A: The main advantages include high precision (0.01mm), fast engraving speeds (400mm/s), a spacious 200mm x 400mm working area, dual voltage compatibility, stability from its robust build, and a long laser life of 3000 hours, making it suitable for sustained, detailed work.Q: Where can this laser engraving machine be installed or set up?

A: Due to its compact dimensions (80x50x31cm) and stable 38kg weight, it can be installed in workshops, studios, factories, or educational labs. It requires a flat, well-ventilated area with access to AC220V or AC110V power outlets and water for the cooling system.Q: How do I maintain optimal performance and ensure laser longevity?

A: To maintain optimal performance, ensure the water cooling system is always functional to prevent overheating, regularly clean the lens and working area, and operate the machine within the recommended temperature (545C) and humidity (5%95%) ranges. Routine checks on power supply and controls are also advised.Q: When should I consider replacing parts or servicing the machine?

A: After approximately 3,000 hours of laser usage or if you notice a drop in engraving quality or precision, its time to check or replace the laser tube and service key mechanical parts. Regular preventive maintenance can extend the machines lifespan.Q: What is the process for switching between different voltage settings?

A: This model supports both AC220V 10%, 50Hz and AC110V, 60Hz. Switching voltage requires setting the appropriate input on the power supply or contacting a qualified technician to make adjustments per the manufacturers instructions, ensuring safe operation.Q: What are the benefits of water cooling for this laser engraving machine?

A: The water cooling system efficiently dissipates heat from the laser tube, preventing overheating during extended operation. This prolongs the life of the laser and maintains consistent performance, especially crucial in high-volume production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free