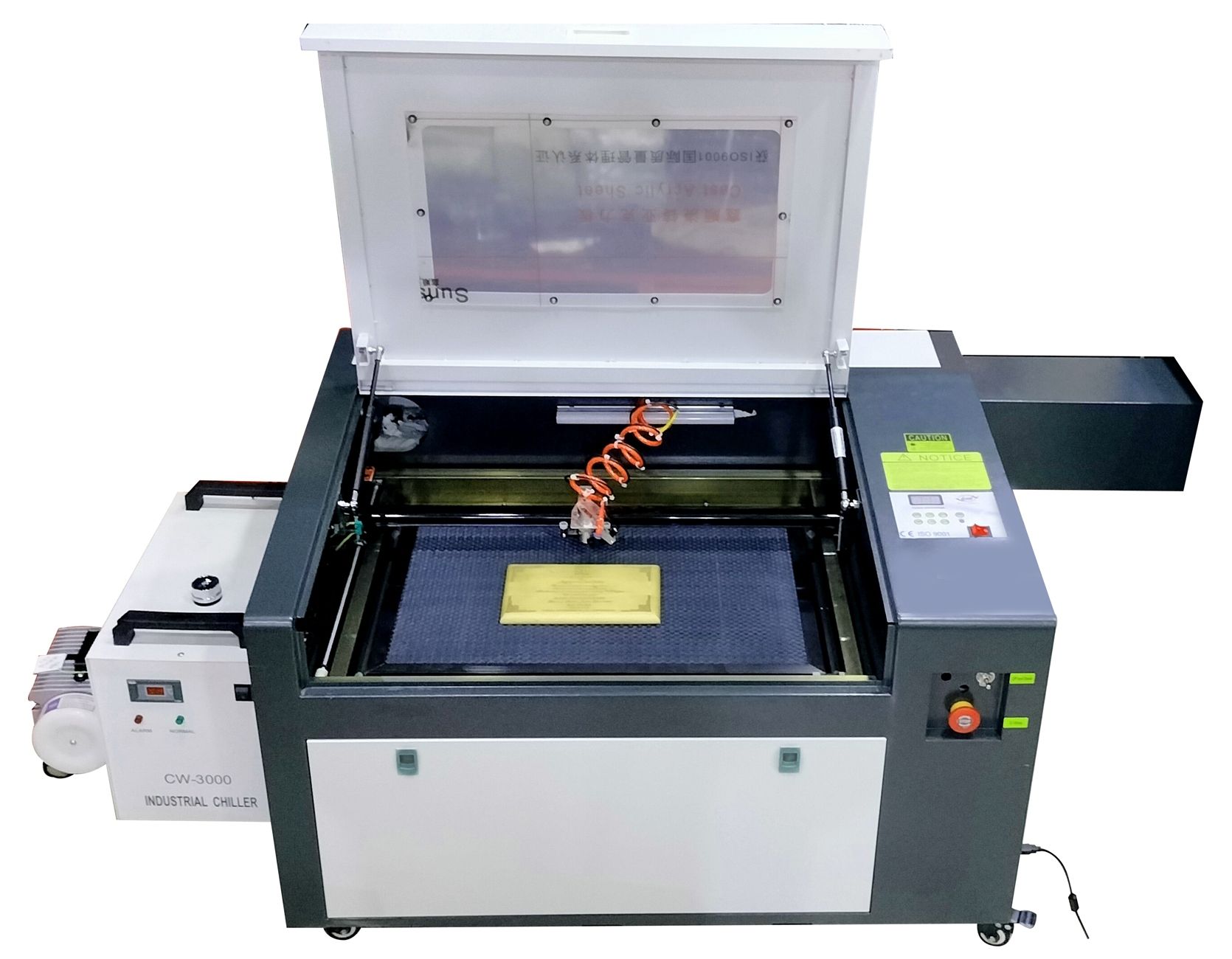

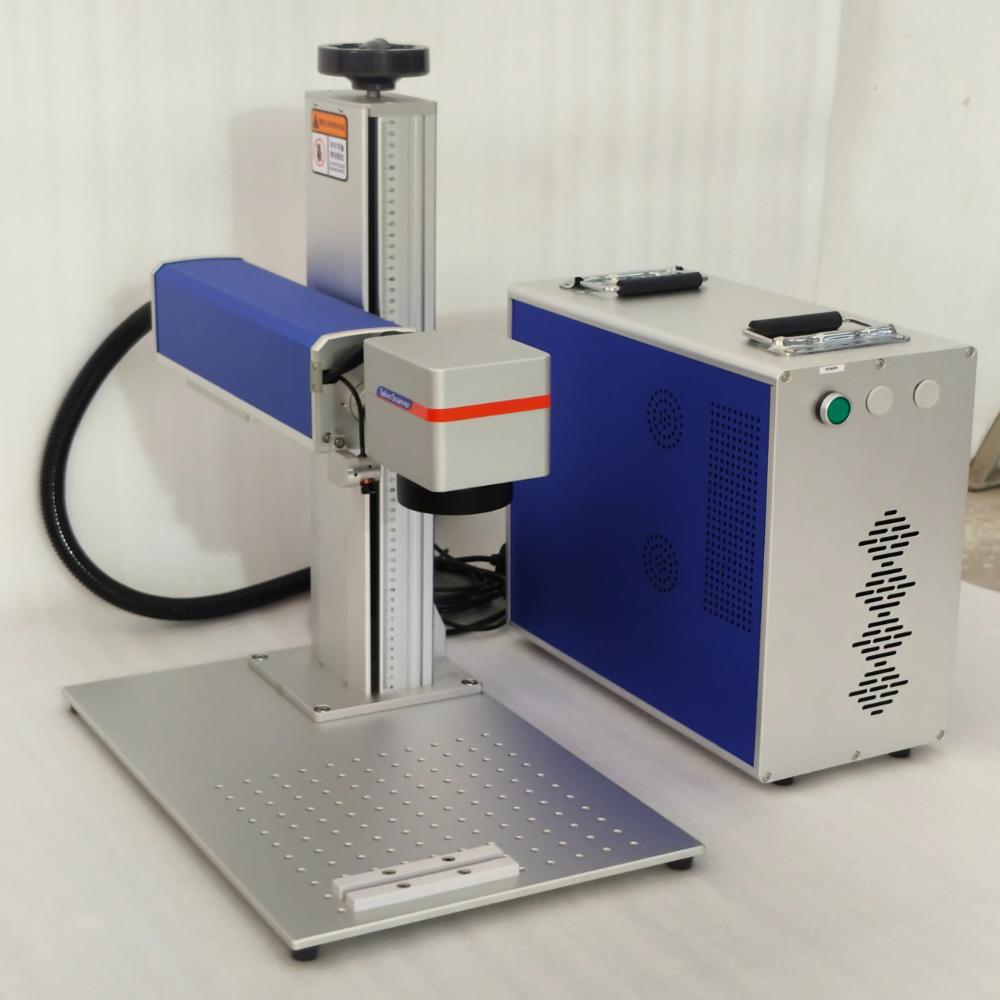

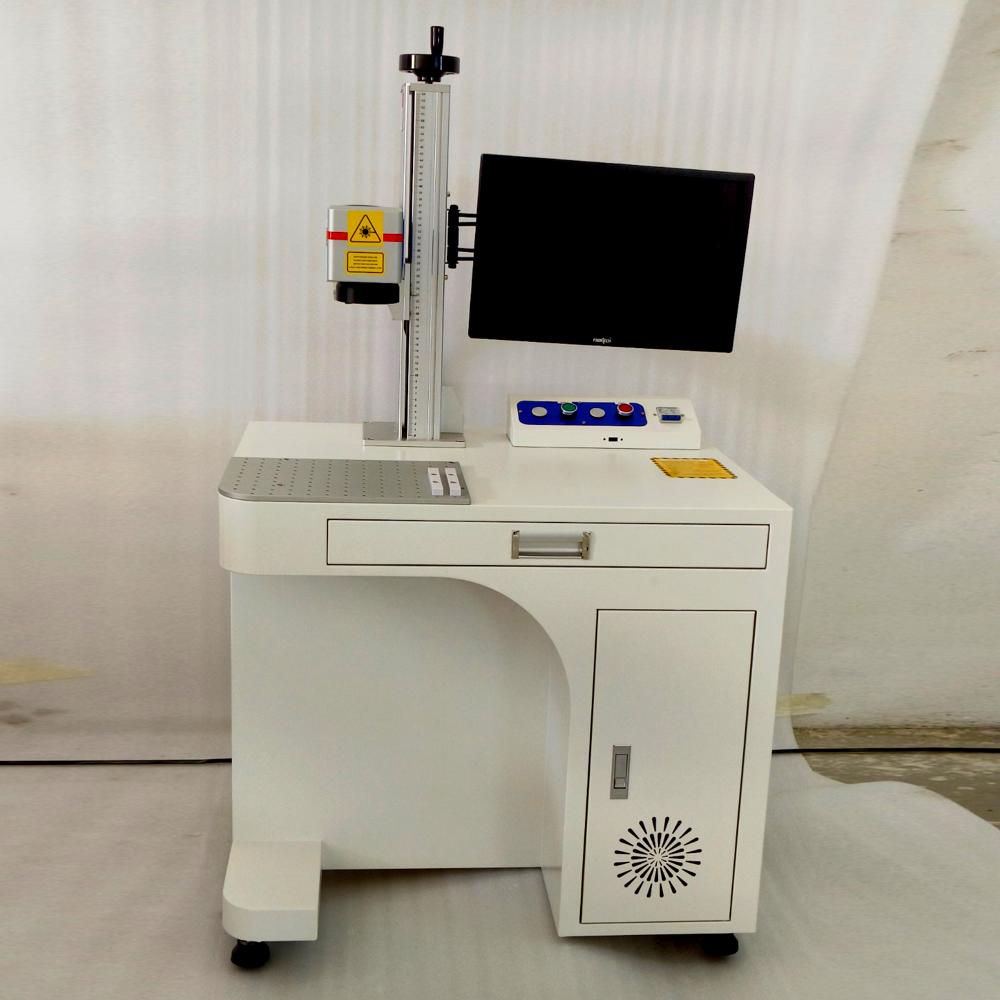

Co2 Acrylic Laser Cutting Machine

150000.00 INR/Piece

Product Details:

- Laser Type CO2

- Cutting Thickness 5 Millimeter (mm)

- Cutting Area 384 Square Inch (in2)

- Cutting Speed 100 mm/s

- CNC Or Not Normal

- Computerized Yes

- Automatic Grade Automatic

- Click to View more

X

Co2 Acrylic Laser Cutting Machine Price And Quantity

- 150000.00 INR/Piece

- 1 Piece

Co2 Acrylic Laser Cutting Machine Product Specifications

- Water Cooling

- CorelLaser

- 1 year

- 5 Millimeter (mm)

- Yes

- Other

- CO2

- 220 Volt (v)

- Automatic

- Normal

- 200 Kilograms (kg)

- 115x82x98 Centimeter (cm)

- PLT

- 384 Square Inch (in2)

- 100 mm/s

Co2 Acrylic Laser Cutting Machine Trade Information

- Kolkata

- Per Day

- 1 Days

- Within a certain price range free samples are available

- Packed in wooden carton with proper Foam cushioning

- All India

Product Description

Acrylic Cutting Machine

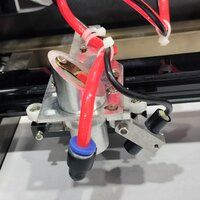

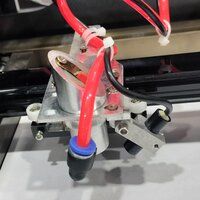

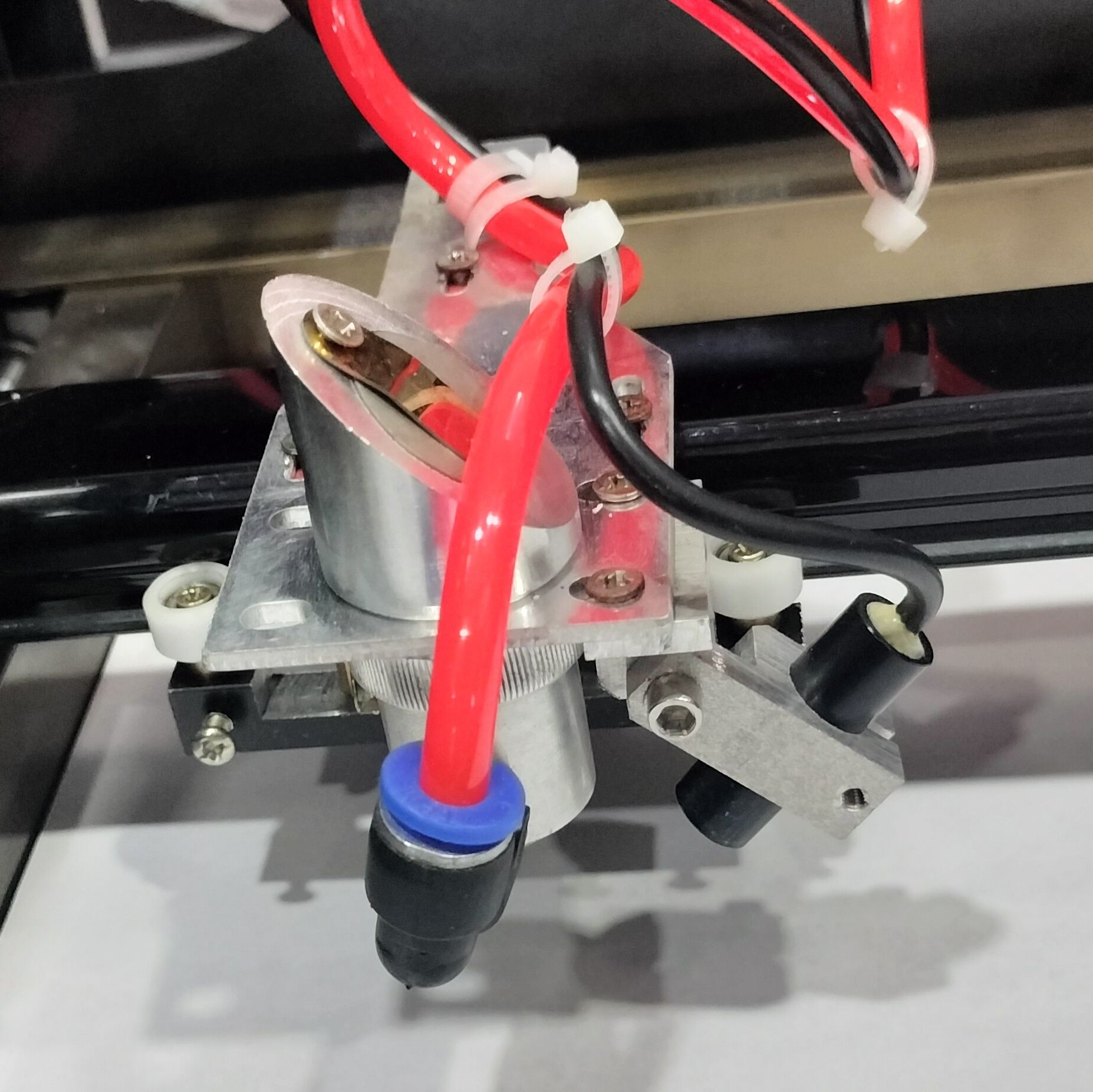

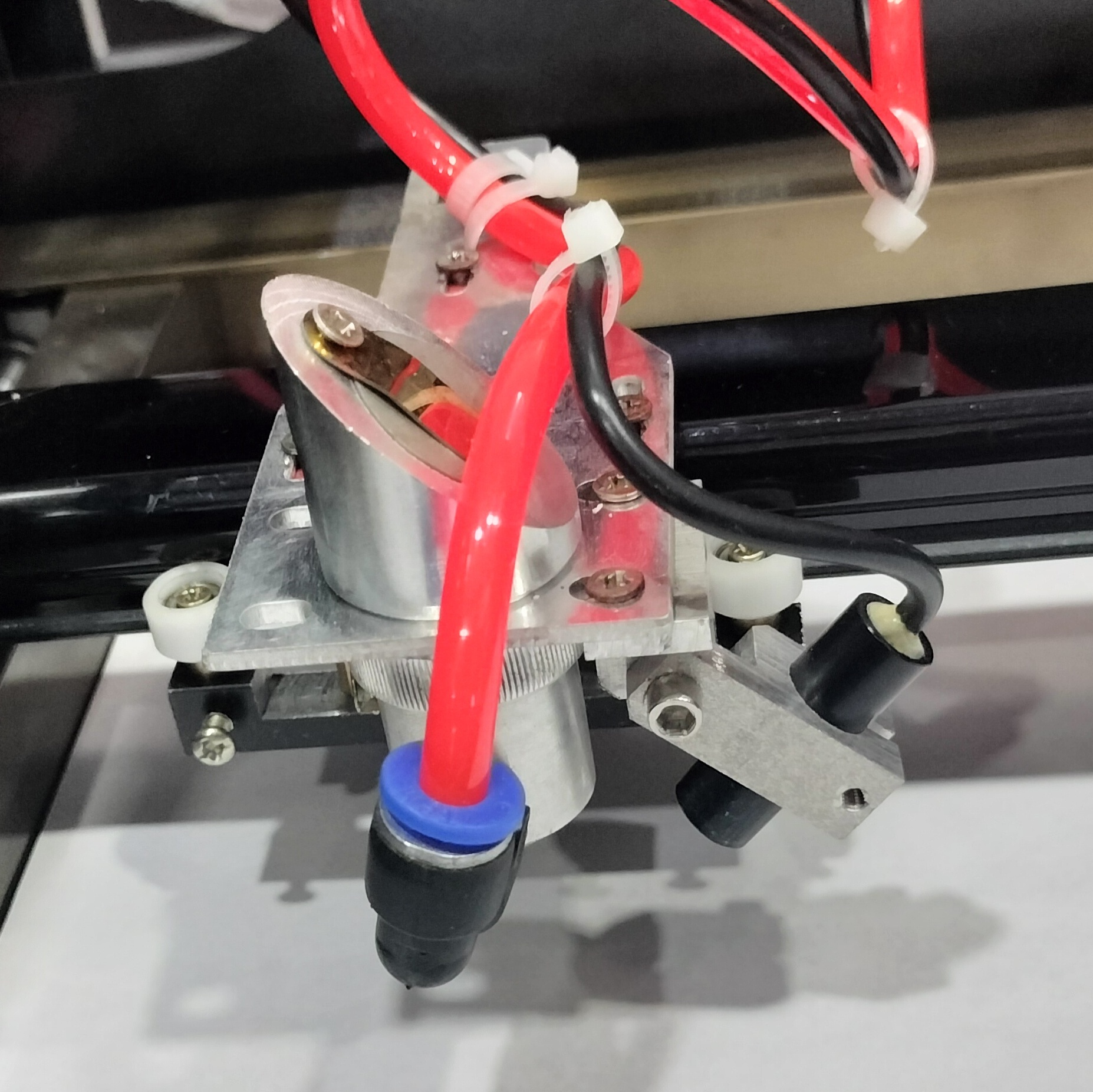

- High Stability Control Card / Driver, Dsp Control And 2h

- Stepper Motor For High Engraving Speed While Ensuring

- Quality. Supports All Major File Formats.

- Powerful Exhaust Fan Sucks Out Smoke & Dust

- From The Machine And Keeps The Machine Clean.

- Imported Highly Stable Guide Rail Improves Precision

- Powerful Water Chiller To Manage Temperature

- Increases Longevity Of Laser Tube

- International Wooden Case Packaging For Utmost Safety

- During Transportation

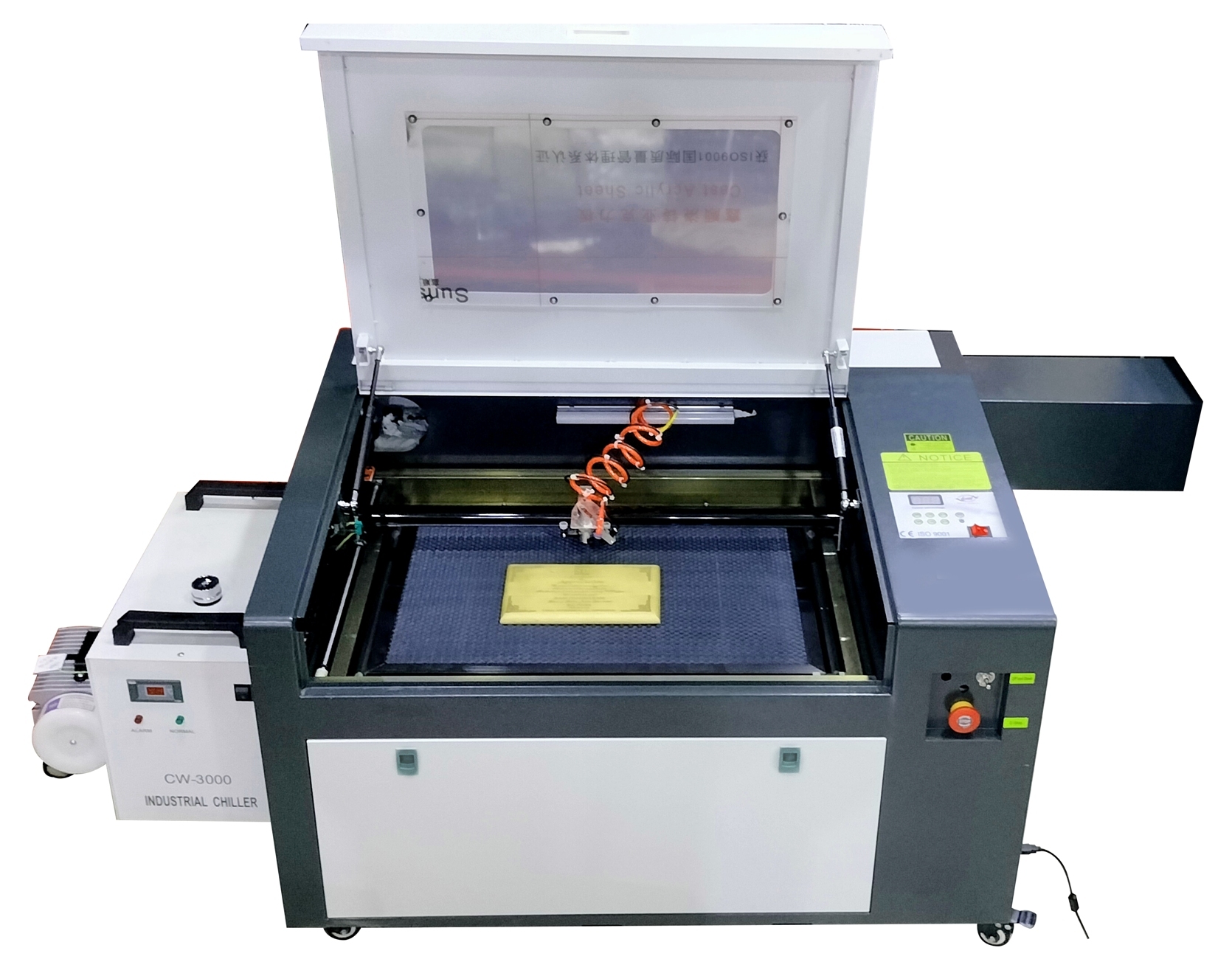

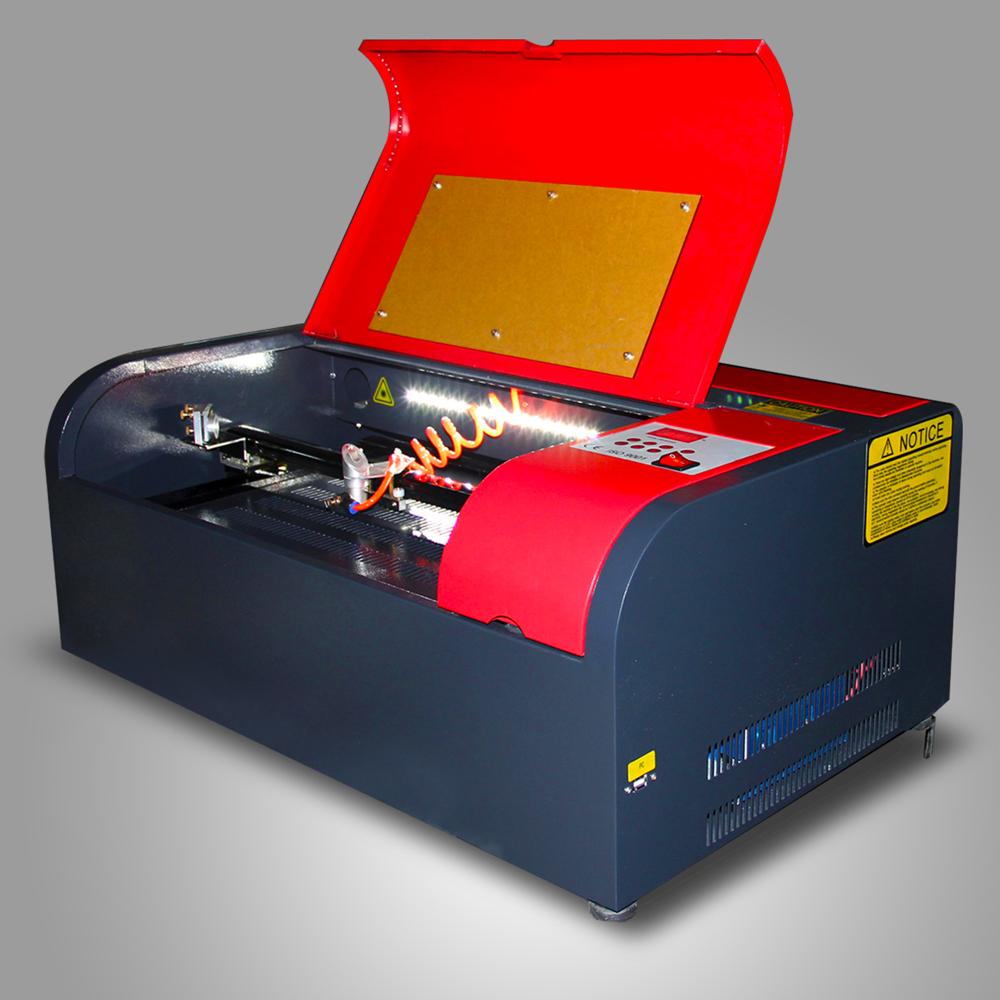

Exceptional Performance and Precision

This laser cutting machine boasts an impressive accuracy level of 0.01mm, ensuring clean and consistent results on every project. Its advanced stepper motor and automatic drive type provide smooth, controlled operation for intricate designs. Whether working on signage, arts, or industrial parts, users can expect flawless output each time.

Adaptable and User-Friendly Operation

The machine is designed with versatility in mind, supporting a wide range of non-metal materials and accommodating various voltages (AC220V or AC110V). The integrated CorelLaser control software and high-stability control card enable easy setup, fast adjustments, and efficient processing for both beginners and professionals.

Durability and Hassle-Free Maintenance

Engineered for long-term use, the CO2 laser has a lifespan of 3000 hours under standard conditions. Its water cooling system ensures optimal working temperatures, even in demanding environments with 5%-95% humidity. Maintenance is straightforward, and the machine is backed by a dependable one-year warranty for peace of mind.

FAQs of Co2 Acrylic Laser Cutting Machine:

Q: How does the CO2 Acrylic Laser Cutting Machine operate?

A: The machine uses a CO2 laser source, directed by an automatic drive and stepper motor, to cut or engrave materials placed on its 600mm x 400mm work area. Operation is controlled through CorelLaser software, providing precise, programmable output according to your design files.Q: What materials can the CO2 laser cutter process?

A: This laser cutting machine is suitable for non-metal materials such as acrylic, wood, leather, fabric, rubber, plastic, MDF, stone, organic glass, coated metals, and more, making it ideal for various industries and creative applications.Q: What are the benefits of using this laser cutting machine?

A: With fast marking speeds (up to 1000mm/s), high accuracy (0.01mm), and an automatic operation mode, you gain efficient production and outstanding result quality. The generous work area allows for both detailed work and bulk jobs, supporting business growth and versatility.Q: How do I maintain the CO2 laser cutter for optimal performance?

A: Routine water cooling system checks, cleaning optical components, and following the manufacturers guidelines will help extend the lasers lifespan (up to 3000 hours). Scheduled maintenance ensures safe and consistent operation.Q: Where is this machine best used?

A: This machine is suitable for workshops, fabrication businesses, educational institutions, and art studios. Its adaptable voltage support and robust build make it ideal for environments in India and similar markets.Q: What warranty and support come with the machine?

A: It comes with a one-year warranty covering manufacturing defects. Distributors, importers, and wholesalers in India provide local support for installation, troubleshooting, and spare parts.Q: When should the CO2 tube be replaced, and what is the replacement process?

A: The CO2 laser tube generally needs replacement after around 3000 hours of use, signaled by reduced cutting quality. The replacement process is straightforward and detailed in the user manual; local distributors can assist if needed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free