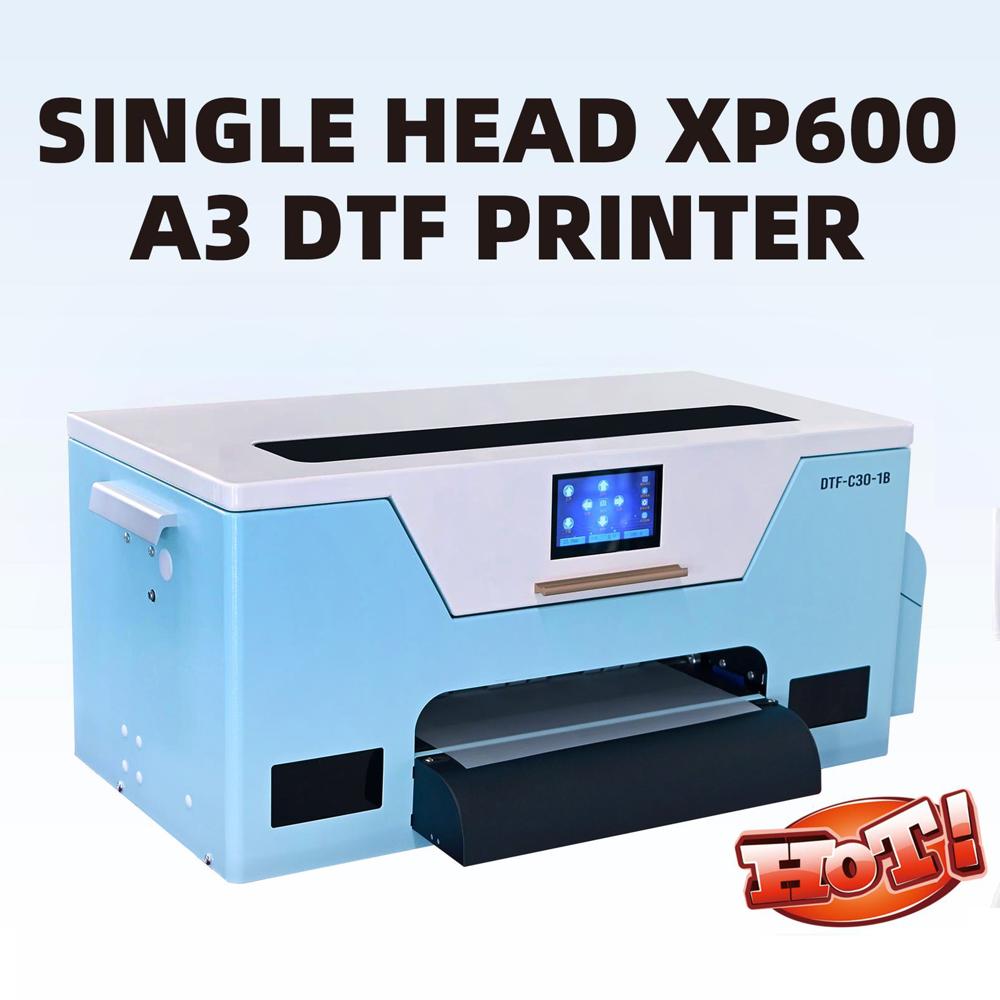

12" DTF (Direct to Film) Printer (Automatic)

299999.0 INR/Unit

Product Details:

- Head Size XP600

- Automatic Grade Automatic

- Condition 15 - 30 degree Centigrade / 50% - 70% Humidity

- Printing Width 11.5 Inch (in)

- Printing Method DTF Printing & Heat Transfer

- Printing Speed 3 m/hr

- Product Type DTF Printer

- Click to View more

X

12" DTF (Direct to Film) Printer (Automatic) Price And Quantity

- 299999.0 INR/Unit

- 1 Unit

12" DTF (Direct to Film) Printer (Automatic) Product Specifications

- XP600

- 120 Kilograms (kg)

- Garment Printing

- DTF Printer

- 144*70*67 Centimeter (cm)

- DTF Printing & Heat Transfer

- 15 - 30 degree Centigrade / 50% - 70% Humidity

- 11.5 Inch (in)

- Automatic

- Multicolor

- 3 m/hr

12" DTF (Direct to Film) Printer (Automatic) Trade Information

- Ex-Kolkata

- Cash Advance (CA)

- 5 Unit Per Week

- 5 Days

- No

- Contact us for information regarding our sample policy

- Printer & Shaker packed in Separate Wooden Carton

- Asia

- All India

- CE Certified

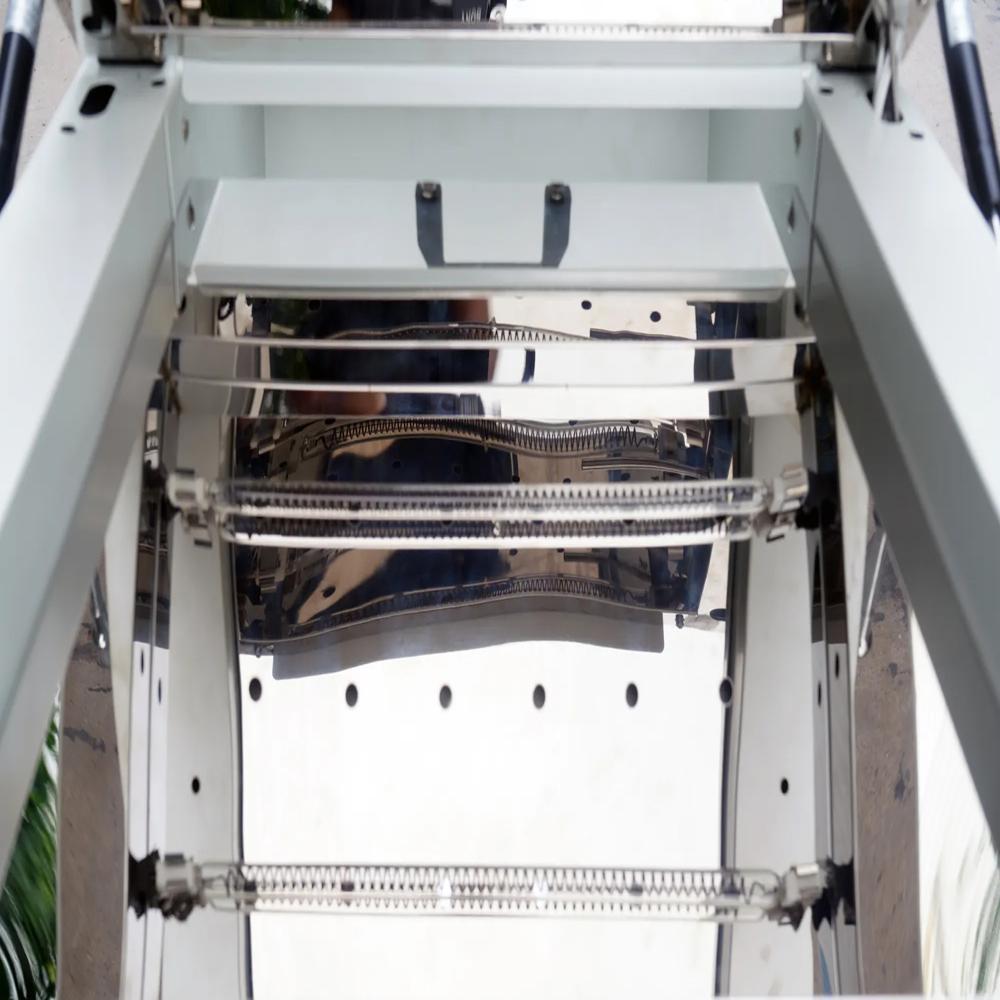

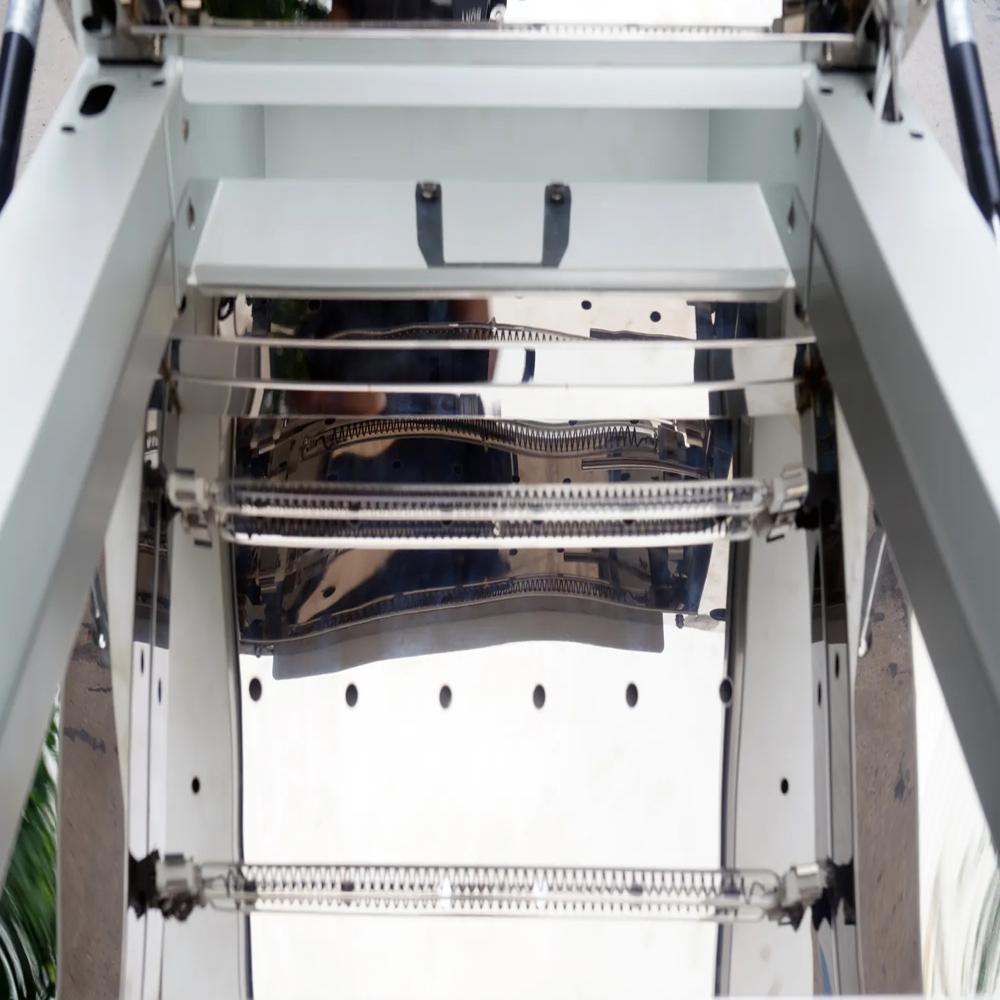

Product Description

BRAND : AUDLEY

MODEL TYPE : DTF-2030-X5

PRINT HEAD : XP600 Dual

PRINT RESOLUTION : 1080 DPI

MAX PRINT SPEED : 3 sqm/h

COLOR CONTROL : ICC COLOR POIL WITH ADJUST UNCTION

PRINT WIDTH : 300mm

RIP Software :Maintop6

INK : TEXTILE PIGMENT INK Cyan/Magenta/Yellow/Black/White

OPERATION ENVIROMENT : 15 - 30 degree Centigrade

50% - 70% Humidity

POWER : 220V Single Phase, 50-60HZ

SYSTEM - WINDOWS 7 OR ABOVE

Production Technique :DTF Printing & Powder Shaking

Size :144*70*67cm

Weight : 120 Kg

Effortless Garment Printing with Superior Precision

Harness the power of automatic technology in garment printing with the 12" DTF Printer featuring the XP600 print head. This model delivers crisp, vibrant designs on a variety of textiles thanks to its multicolor capabilities and precise temperature and humidity controls. Designed for streamlined operations, it meets the demands of busy printing businesses while ensuring consistent results.

Optimized Performance for Indian Production Environments

Built for convenience, this printer operates best in Indian climate conditions, requiring only standard indoor temperatures and humidity levels. Its automatic grade and robust design provide a reliable, consistent printing process, saving labor costs and minimizing errors during garment production.

FAQs of 12" DTF (Direct to Film) Printer (Automatic):

Q: How does the 12" DTF Printer improve garment printing efficiency?

A: The 12" DTF Printer automates the printing process with its advanced XP600 head and automatic feed, ensuring consistent multicolor prints on garments. Its 3 meters per hour speed allows for faster production, making it ideal for commercial use.Q: What environmental conditions does the printer require for optimal operation?

A: For peak performance, the printer should be operated in temperatures between 1530C and humidity levels of 50%70%. Adhering to these conditions helps maintain output quality and prolongs the machines lifespan.Q: When should the heat transfer method be used with this printer?

A: The heat transfer method is used after printing the design on the film. It is essential for permanently affixing the image onto the garment fabric, ensuring durability and vibrant color retention.Q: Where is this DTF printer commonly used in India?

A: This printer is popular in garment production units, print shops, and textile mills across India, particularly those focusing on high-quality multicolor apparel output.Q: What is the process for operating the 12" DTF Printer?

A: Simply load the film, select your design, and let the automatic printing and heat transfer process commence. Minimal manual intervention is needed, and the user-friendly interface supports streamlined operation.Q: What garments can benefit from DTF printing with this machine?

A: The printer is suitable for a wide array of fabrics and garments, including t-shirts, hoodies, uniforms, and more, delivering vibrant, long-lasting prints regardless of material type.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'DTF Printer' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS