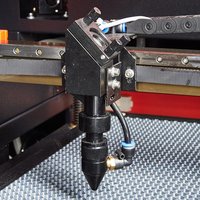

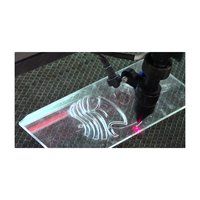

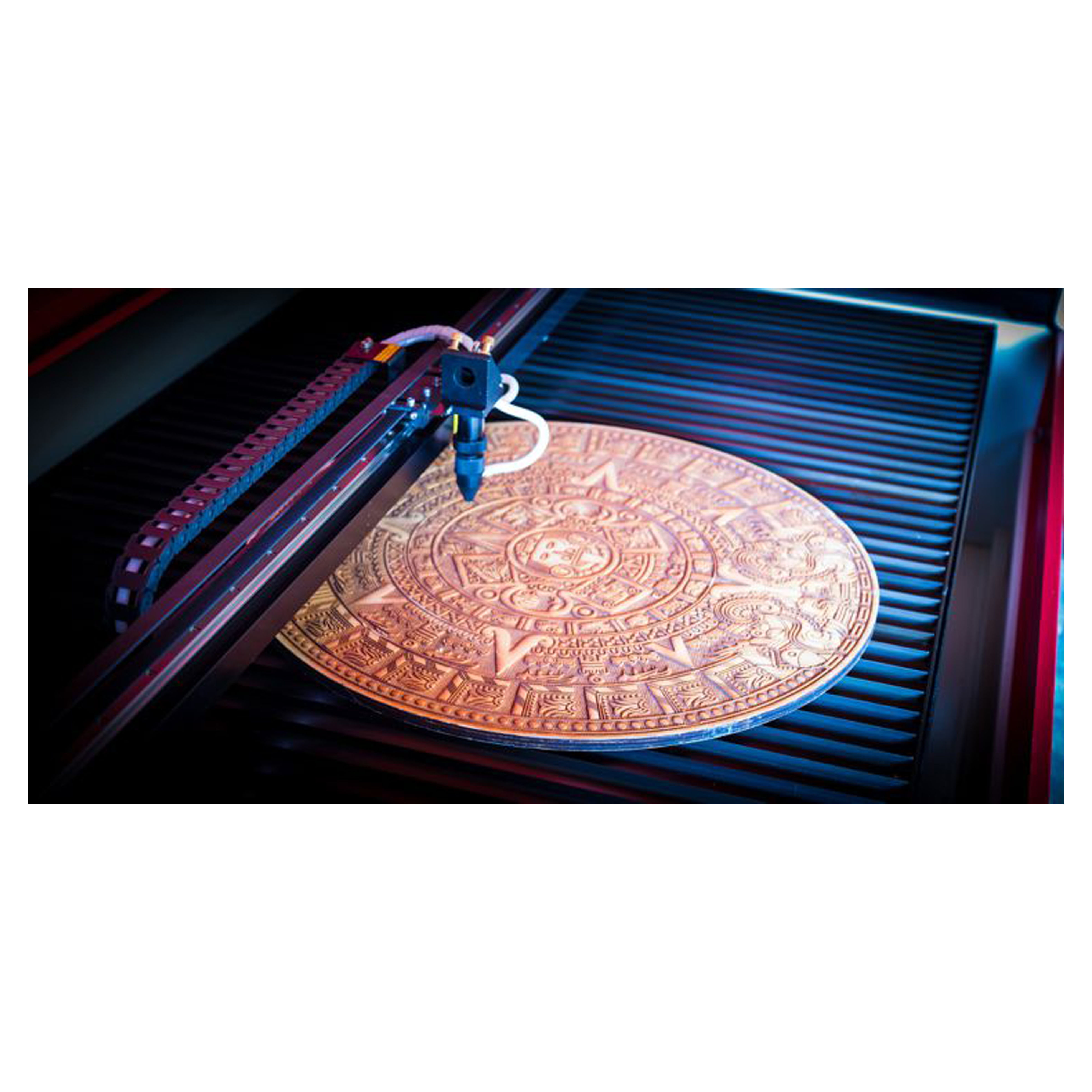

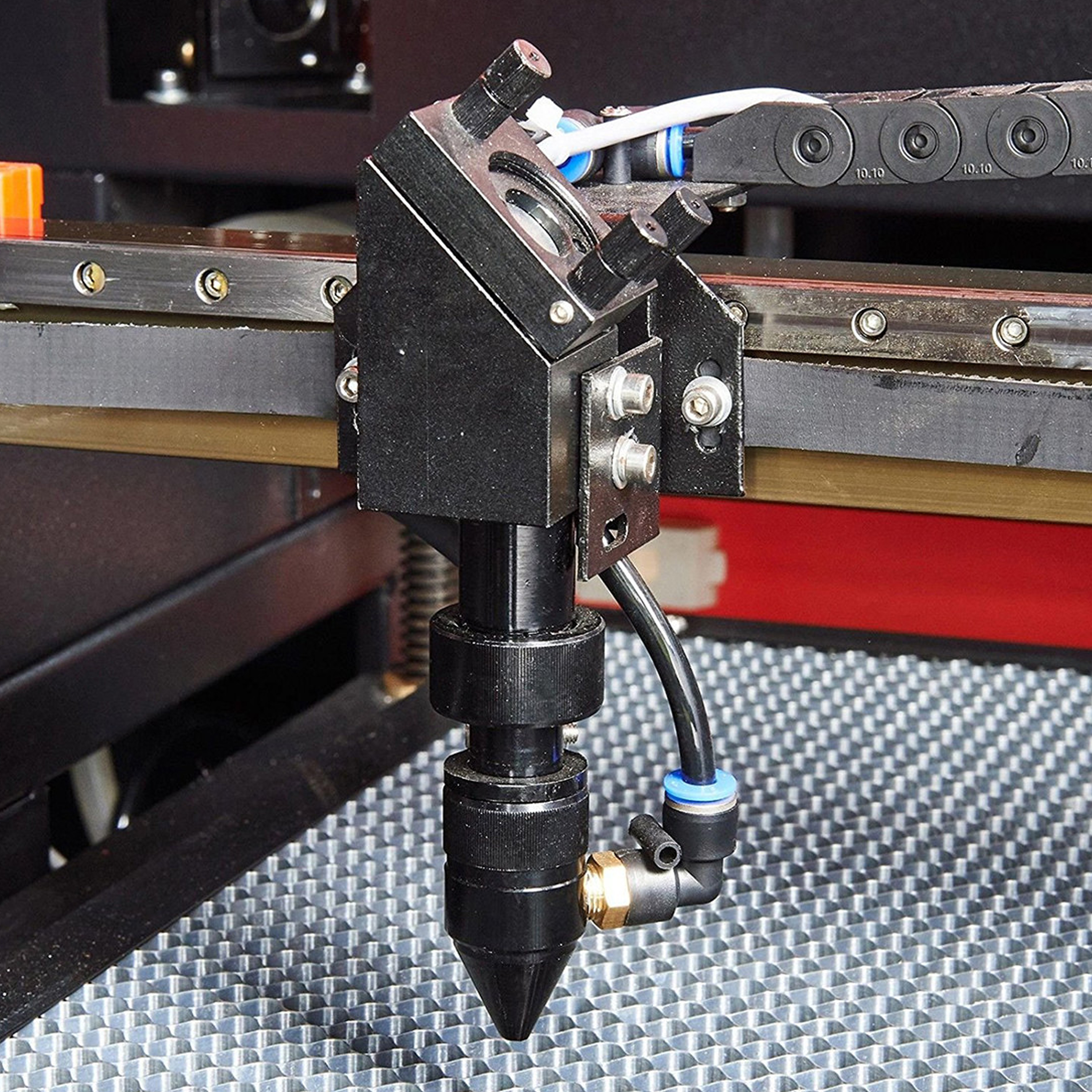

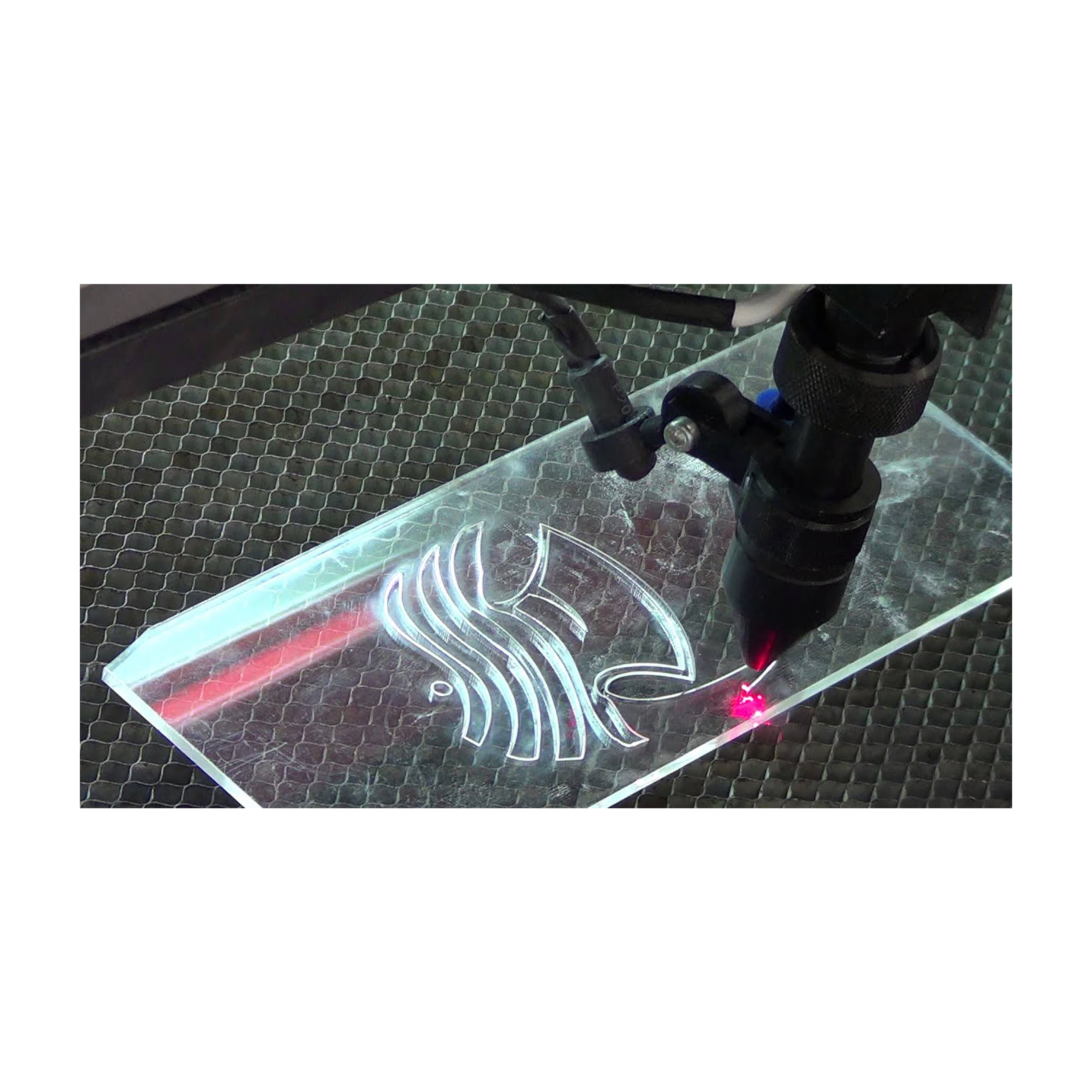

Co2 Laser Cutting Machine

150000-175000 INR/Piece

Product Details:

X

Co2 Laser Cutting Machine Price And Quantity

- 150000.00 - 175000.00 INR/Piece

- 150000-175000 INR/Piece

- 1 Piece

Co2 Laser Cutting Machine Trade Information

- Kolkata

- 1-20 Piece Per Day

- 1 Days

- Within a certain price range free samples are available

- All India

Product Description

Mdf Board Cutting Machine- High stability control card / driver, DSP control and 2h stepper motor for high engraving speed while ensuring quality. Supports all major file formats.

- Powerful exhaust fan sucks out smoke & dust from the machine and keeps the machine clean.

- Imported highly stable guide rail improves precision

- Powerful water chiller to manage temperature increases longevity of laser tube

- International wooden case packaging for utmost safety during transportation

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Laser Cutting Machine' category

"We are dealing only in bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS